Tube and Rest

Once a swatch is knitted, the normal instruction is to

"TUBE" the

swatch and let it rest for 24 hours.

To tube, grasp the cast-on edge in one hand and the bind-off edge in the other hand and pull.

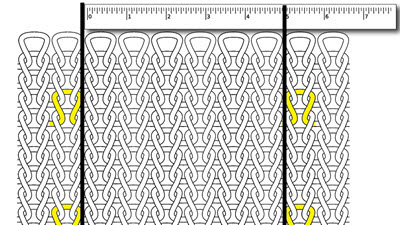

- The needle

spacing (4.5mm, 7mm, 9mm, etc.) on the machine creates an unnatural gap between the heads of the stitches.

- The tensions of the mast and tension dial impede the flow of yarn and cause it to

stretch.

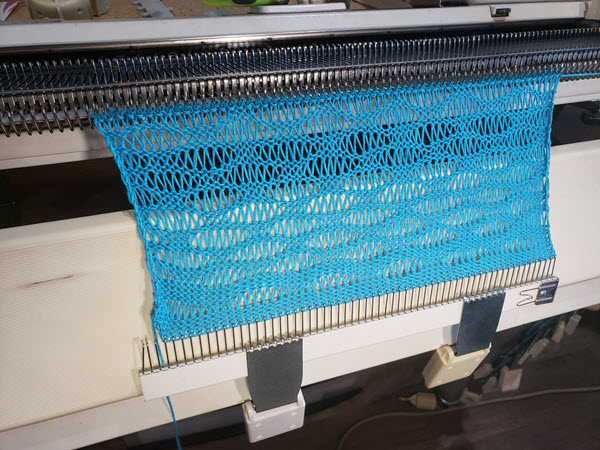

- The knitting is stretched across the needlebed

- Weights on the knitting also tends to stretch it

Tubing corrects these problems by pulling this needle-spacing yarn into the stitch.

The 24-hour rest period allows the yarn to return to normal size.

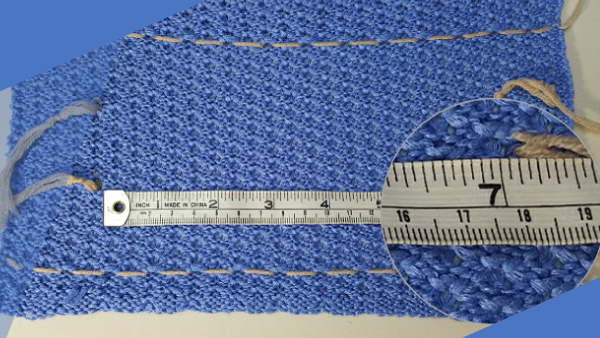

Recording the measurements

of several swatches before and after resting will demonstrate this change.

The stitches are set during blocking or washing. It is necessary to treat the swatch in the same

order of resting, blocking, and washing, that you treat the garment in order to

obtain the same gauge on both swatch and garment